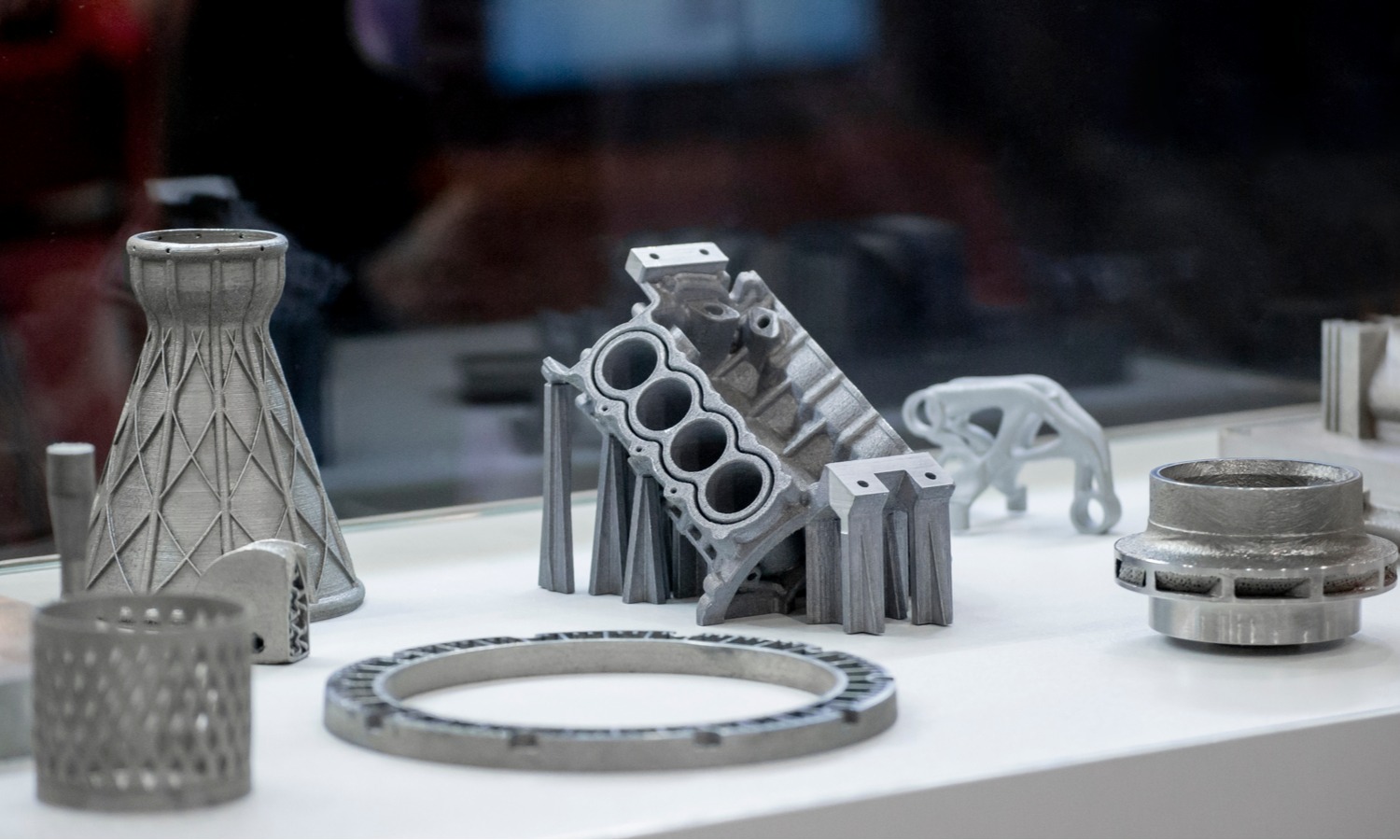

The advent of 3D printing, also known as additive manufacturing, has revolutionized many industries, including welding. The combination of 3D printing and traditional welding techniques offers numerous advantages, enabling the creation of complex structures with enhanced precision and efficiency. This article explores the integration of 3D printing in welding, providing examples of applications and discussing the benefits of this innovative approach.

The Synergy of 3D Printing and Welding

3D printing involves creating objects layer by layer from digital models, while welding traditionally involves joining materials by melting them together. The integration of these technologies leverages the strengths of both, resulting in enhanced manufacturing capabilities.

Hybrid Manufacturing: Combining 3D printing with welding processes creates hybrid manufacturing techniques that offer greater flexibility and precision. This integration allows for the production of complex geometries that would be challenging or impossible to achieve with traditional methods alone.

Efficacité des matériaux: 3D printing minimizes material waste by adding only the necessary material layer by layer. When combined with welding, this can lead to significant cost savings, especially in industries where material costs are high.

Customization and Prototyping: 3D printing enables rapid prototyping and customization of parts, which can then be welded into larger assemblies. This capability is invaluable for industries that require bespoke solutions or iterative design processes.

Applications de l'impression 3D dans le domaine du soudage

- Industrie aérospatiale

The aerospace industry benefits significantly from the integration of 3D printing and welding. Lightweight, high-strength components are essential in this sector, and the combined technologies allow for the creation of such parts with high precision.

- Complex Engine Parts: 3D printing is used to create intricate engine components that are then welded into larger assemblies. This approach ensures high strength and reduces the weight of the parts, improving fuel efficiency.

- Réparation et entretien: Damaged aerospace components can be repaired using 3D printing to add material to the affected areas, followed by precision welding to restore the part’s integrity.

- Industrie automobile

In the automotive sector, 3D printing and welding are used to produce customized and high-performance parts. This combination enhances the design flexibility and production speed.

- Prototyping and Testing: Automotive manufacturers use 3D printing to create prototypes of parts, which are then tested and refined. Welding is used to assemble these prototypes into full-scale models for further evaluation.

- Lightweight Structures: The production of lightweight, durable components is critical for improving vehicle efficiency. 3D printing allows for the creation of such parts, which are then welded into the vehicle’s structure.

- Dispositifs médicaux

The medical industry requires highly precise and customizable components, which can be efficiently produced using 3D printing and welding.

- Custom Implants: 3D printing is used to produce patient-specific implants, which are then welded to ensure structural integrity and biocompatibility.

- Instruments chirurgicaux: Complex surgical instruments are manufactured using 3D printing for their intricate designs, followed by welding to assemble multiple parts into a functional tool.

- Construction et infrastructure

3D printing and welding are increasingly used in construction and infrastructure projects to create durable and customized components.

- Structural Components: Large-scale 3D printers can create structural components that are welded together to form robust frameworks for buildings and bridges.

- Restoration Projects: For restoring historical structures, 3D printing is used to recreate damaged parts, which are then welded into place, preserving the original design.

Benefits of Combining 3D Printing and Welding

- Enhanced Design Flexibility

The integration of 3D printing and welding allows for greater design flexibility. Complex geometries and intricate designs can be easily produced, which would be challenging to achieve with traditional manufacturing methods alone.

- Improved Efficiency and Speed

Combining these technologies streamlines the production process, reducing the time required to move from design to finished product. Rapid prototyping and iterative testing are facilitated, speeding up development cycles.

- Économies de coûts

Material efficiency and reduced waste result in significant cost savings. The ability to produce parts on-demand and in-house also reduces the need for large inventories and external suppliers.

- Customization and Personalization

3D printing enables the production of highly customized parts tailored to specific requirements. This is particularly beneficial in industries like healthcare, where patient-specific solutions are often needed.

- Reduced Lead Times

The combination of 3D printing and welding reduces lead times by enabling the rapid production and assembly of parts. This is especially important in industries where time-to-market is critical.

Challenges and Future Prospects

While the integration of 3D printing and welding offers numerous benefits, there are also challenges to consider.

- Compatibilité des matériaux: Ensuring compatibility between 3D printed materials and welding processes can be challenging. Ongoing research is focused on developing materials that work seamlessly with both technologies.

- Contrôle de la qualité: Maintaining consistent quality across the production process is essential. Advanced monitoring and control systems are being developed to ensure high standards are met.

- Skill Requirements: The use of these advanced technologies requires specialized skills. Investing in training and education for workers is crucial to fully leverage the potential of 3D printing and welding.

Conclusion

The integration of 3D printing and welding represents a significant advancement in manufacturing technology. By combining the precision and flexibility of 3D printing with the strength and reliability of welding, industries can produce complex, high-quality components more efficiently and cost-effectively. As these technologies continue to evolve, their applications will expand, offering even greater opportunities for innovation and improvement across various sectors. Embracing these advancements will be key to staying competitive in the rapidly changing landscape of modern manufacturing.