Tungsten Inert Gas (TIG) welding, also known as Gas Tungsten Arc Welding (GTAW), is a versatile welding process celebrated for its precision, quality, and suitability for a wide range of metals. This article explores the numerous advantages that TIG welding offers, making it a preferred choice in various industries.

Precision and Quality

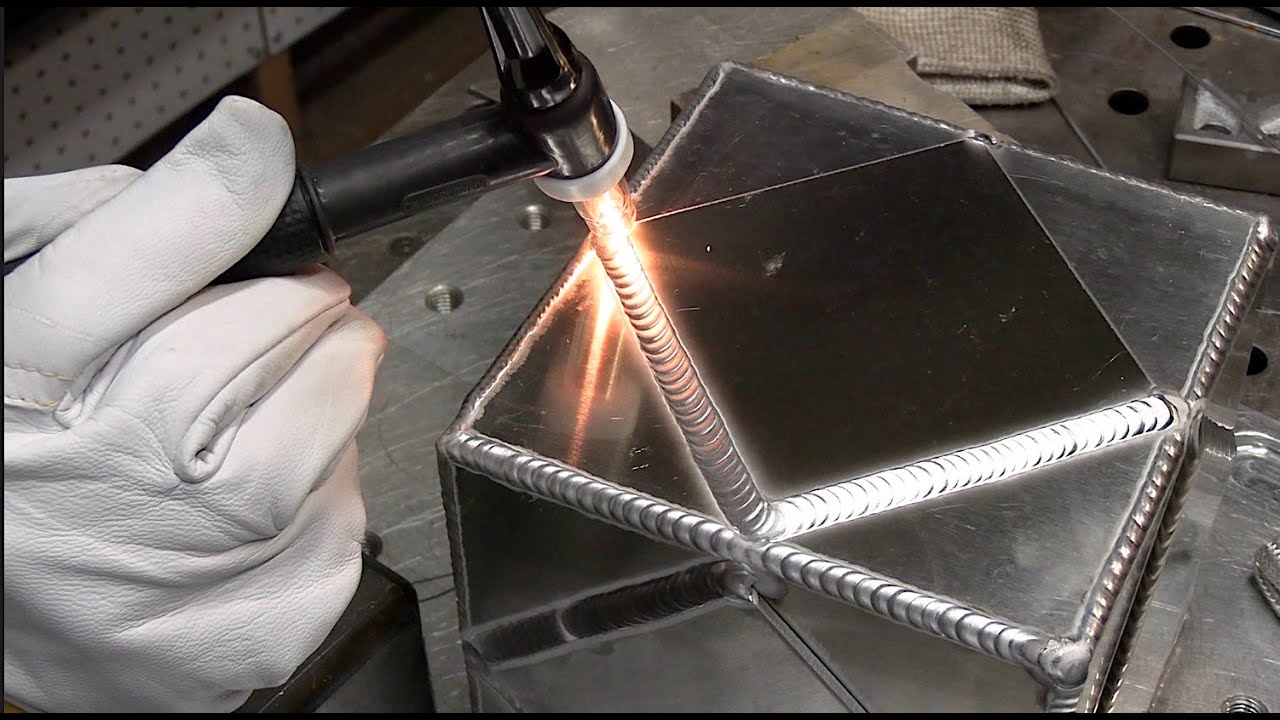

One of the primary advantages of TIG welding is its exceptional precision. The process allows welders to achieve precise control over the heat input, arc length, and filler material deposition. This level of control results in high-quality welds with minimal distortion, ensuring superior strength and aesthetic appeal. TIG welding is particularly favored for applications where weld appearance and structural integrity are critical, such as in aerospace, automotive, and semiconductor industries.

Versatility with Various Metals

TIG welding is compatible with a wide range of metals and alloys, including stainless steel, aluminum, nickel alloys, titanium, and copper. The process accommodates both thin and thick materials, making it suitable for welding intricate components as well as heavy structural pieces. Its ability to weld dissimilar metals together further expands its application scope, offering flexibility in manufacturing and repair processes.

Cleanliness and Weld Aesthetics

Compared to other welding methods, TIG welding produces exceptionally clean welds with minimal spatter and fumes. The inert gas shielding (typically argon or helium) protects the weld pool from atmospheric contamination, resulting in welds free from oxidation and porosity. This cleanliness not only enhances the mechanical properties of the weld but also reduces the need for post-weld cleaning or finishing, thereby saving time and labor costs.

Control over Heat and Welding Parameters

TIG welding provides welders with precise control over heat input and welding parameters. The non-consumable tungsten electrode, combined with a foot pedal or fingertip control, allows operators to adjust the arc length and welding current in real-time. This level of control is crucial for welding thin materials or components where heat sensitivity is a concern, ensuring minimal distortion and preserving material properties.

Suitable for Complex Joint Configurations

The versatility of TIG welding extends to its capability to weld complex joint configurations, including fillet welds, butt joints, and corner joints. Its ability to produce strong and visually appealing welds in challenging positions or tight spaces makes it indispensable in industries where component design demands intricate welding solutions.

Conclusion

In conclusion, TIG welding stands out as a premier welding process due to its precision, versatility, and ability to produce high-quality welds across a wide range of materials. Its cleanliness, control over welding parameters, and suitability for complex applications make it a preferred choice for industries demanding top-notch weld quality and aesthetic appeal.

Whether used in aerospace, automotive, or other precision industries, TIG welding continues to demonstrate its value by consistently delivering superior weld performance and meeting stringent quality standards. Its versatility and ability to weld various metals ensure its relevance in both traditional manufacturing and emerging technological applications.