The manufacturing industry is undergoing a significant transformation, driven by the integration of robotic welding systems. As companies strive for greater efficiency, precision, and cost-effectiveness, robotic welding emerges as a pivotal innovation. This article delves into the advancements in robotic welding and highlights the crucial role of specialized equipment, such as GPPH’s octagonal welding tables, in optimizing these automated processes.

The Evolution of Robotic Welding

Robotic welding has revolutionized traditional welding practices by automating complex and repetitive tasks, thereby enhancing productivity and consistency. Unlike manual welding, which is prone to human error, robotic systems ensure uniformity and precision in every weld. This technological leap is particularly beneficial in industries requiring high volumes of identical welds, such as automotive manufacturing, aerospace, and heavy machinery production.

Key benefits of robotic welding include:

- Verhoogde productiviteit: Robots can operate continuously without fatigue, significantly boosting production rates.

- Enhanced Quality: Automation reduces the likelihood of defects, ensuring high-quality, consistent welds.

- Kostenefficiëntie: While the initial investment in robotic systems is substantial, the long-term savings from reduced labor costs and fewer defects make it a cost-effective solution.

- Safety Improvements: Robots can handle hazardous welding environments, minimizing the risk to human workers.

The Critical Role of Welding Tables

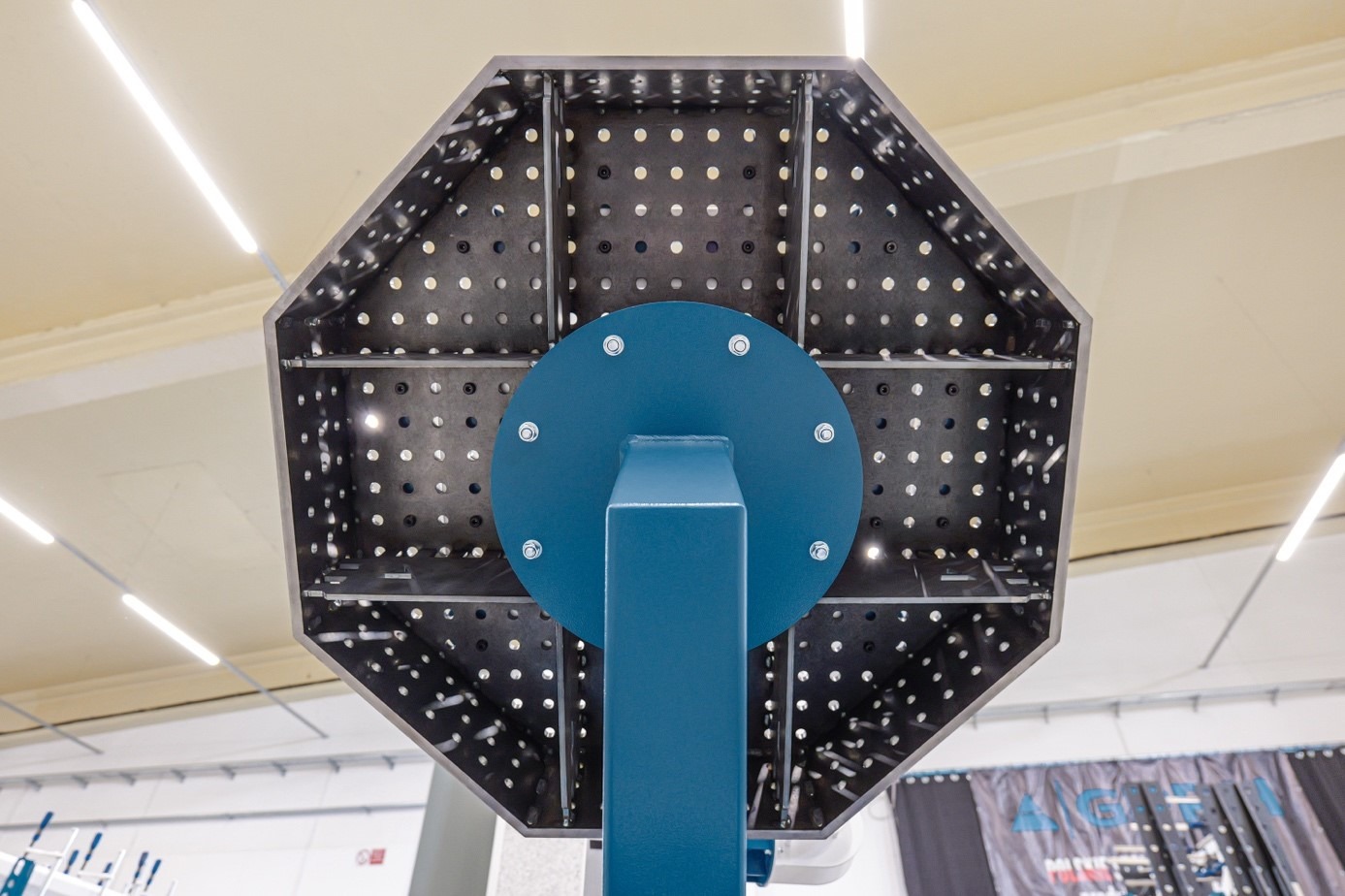

Integral to the success of robotic welding is the use of specialized welding tables. These tables provide the foundation for precise and stable welding operations, ensuring that the robotic arms can function with optimal accuracy. Among the various designs, octagonal welding tables from GPPH stand out for their innovative features tailored to robotic systems.

Octagonal Welding Tables by GPPH

GPPH’s octagonal welding tables are specifically designed to meet the demands of modern robotic welding applications. Their unique shape and robust construction offer several advantages:

- Enhanced Precision: The octagonal design allows for precise positioning of parts, which is critical in automated welding where every millimeter counts.

- Versatile Application: These tables are compatible with a variety of welding robots, making them suitable for diverse industrial applications.

- Durability and Stability: Made from high-quality materials, GPPH tables ensure stability and longevity, even under intense usage.

- Seamless Integration: The tables feature special mounting points and holes, facilitating easy integration with automation systems and speeding up production line setups.

- Optimized Workspace: The octagonal shape optimizes the use of workspace, a crucial factor in manufacturing plants where space is at a premium.

For more details on the features and specifications of octagonal welding tables, visit this page.

Case Studies: Industries Benefiting from Robotic Welding

- Auto-industrie: Robotic welding systems are extensively used in the automotive sector for tasks such as spot welding and arc welding, enhancing the speed and precision of vehicle assembly.

- Ruimtevaart: In aerospace manufacturing, the demand for precise and reliable welds makes robotic systems indispensable. These systems help in welding complex components that are critical for flight safety.

- Construction and Heavy Machinery: For industries involved in constructing large steel structures and heavy machinery, robotic welding ensures the strength and durability of the welds, which are essential for structural integrity.

Future Prospects and Challenges

As technology continues to advance, the integration of AI and machine learning with robotic welding systems promises to further enhance their capabilities. AI can enable predictive maintenance, real-time quality control, and adaptive welding processes, where the system can adjust parameters based on the specific requirements of each weld.

However, the adoption of robotic welding is not without challenges. The high initial cost, the need for specialized training for operators, and the integration with existing systems can be significant hurdles for some companies. Nonetheless, the long-term benefits and the rapid return on investment make it a compelling choice for forward-thinking manufacturers.

Conclusie

Robotic welding is reshaping the landscape of industrial manufacturing, offering unprecedented levels of efficiency, quality, and safety. Central to this transformation are innovations such as GPPH’s octagonal welding tables, which provide the necessary support and precision for these advanced systems. As the technology evolves, the continued collaboration between equipment manufacturers and industry players will be key to unlocking the full potential of robotic welding.

For more insights into advanced welding solutions, visit the GPPH Group website.