Welding tables are a fundamental component in any welding setup, providing a stable and versatile surface for various welding tasks. However, the functionality and efficiency of these tables can be significantly enhanced with the right accessories. This article explores the essential accessories for welding tables and how they can improve your workflow.

Clamping Tools

1. Clamps and Hold-Downs: Clamps and hold-downs are vital for securing workpieces during welding. They provide stability, ensuring precision and safety.

- Toggle Clamps: Toggle clamps are adjustable and offer strong, quick-release mechanisms, making them ideal for repetitive tasks.

- Hold-Down Clamps: These are essential for holding workpieces firmly in place, preventing movement during welding.

2. Magnetic Clamps: Magnetic clamps offer flexibility and ease of use, especially for holding ferrous materials.

- Adjustable Magnetic Clamps: These clamps can be adjusted to various angles, providing support for complex welds.

- On/Off Magnetic Clamps: With the ability to switch the magnetic force on and off, these clamps offer convenience and safety.

Positioning Tools

1. Angle and Corner Squares: Accurate positioning is crucial in welding, and angle and corner squares ensure precise alignment.

- Adjustable Angle Squares: These tools can be set to various angles, aiding in the creation of complex joints.

- Corner Squares: Ideal for maintaining 90-degree angles, corner squares ensure the accuracy of right-angle joints.

2. V-Blocks and U-Blocks: V-blocks and U-blocks are used for holding cylindrical objects and other irregularly shaped workpieces.

- V-Blocks: Perfect for round and cylindrical parts, V-blocks provide stable support during welding.

- U-Blocks: These blocks are versatile, accommodating a range of shapes and sizes, making them useful for diverse welding tasks.

Fixtures and Stops

1. Stop Bars and Stop Angles: Stop bars and angles are used to set up repeatable stops for workpieces, enhancing consistency and efficiency.

- Adjustable Stop Bars: These bars can be adjusted to precise lengths, ensuring uniformity in repetitive tasks.

- Stop Angles: Used to maintain consistent angles, stop angles are essential for tasks requiring precise angular positioning.

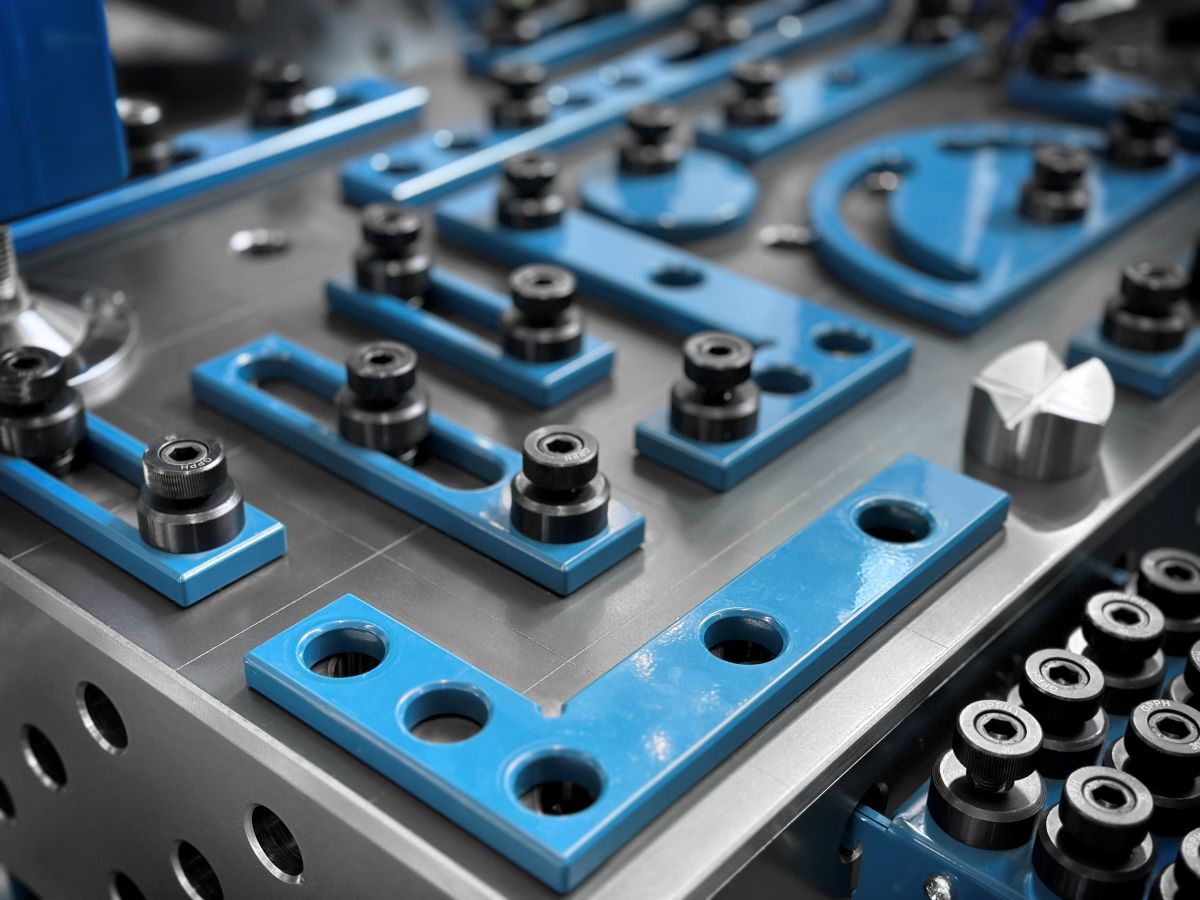

2. Modular Fixture Kits: Modular fixture kits offer flexibility, allowing welders to set up custom fixtures for complex projects.

- Quick-Change Fixture Kits: These kits allow for rapid setup and adjustment, improving workflow and reducing downtime.

- Customizable Kits: Modular kits can be tailored to specific project needs, providing versatility and precision.

Measuring Tools

1. Measuring Tapes and Rules: Accurate measurement is crucial in welding, and high-quality measuring tapes and rules are indispensable.

- Steel Measuring Tapes: Durable and precise, steel tapes provide reliable measurements for various welding tasks.

- Digital Calipers: Offering high precision, digital calipers are essential for detailed measurements and fine adjustments.

2. Angle Gauges and Protractors: Angle gauges and protractors ensure accurate angle measurements, critical for precision welding.

- Digital Angle Gauges: These provide exact angle readings, enhancing accuracy and efficiency.

- Protractors: Traditional protractors are useful for quick, on-the-fly angle measurements, complementing digital tools.

Safety Accessories

1. Welding Curtains and Screens: Welding curtains and screens protect welders and bystanders from sparks and harmful radiation.

- Adjustable Welding Screens: These can be positioned around the work area, providing flexible protection.

- Flame-Resistant Curtains: Made from durable, flame-resistant materials, these curtains enhance safety in the welding environment.

2. Fume Extraction Systems: Effective fume extraction is essential for maintaining air quality and protecting welder health.

- Portable Fume Extractors: These units can be moved to different work areas, offering flexible and efficient fume extraction.

- Fixed Extraction Systems: Installed above welding tables, these systems provide continuous, reliable fume extraction.

Storage Solutions

1. Tool Racks and Holders: Organizing tools and accessories is crucial for maintaining an efficient workspace.

- Magnetic Tool Holders: These holders keep tools within easy reach, reducing downtime and improving workflow.

- Custom Tool Racks: Designed to hold specific tools and accessories, custom racks enhance organization and accessibility.

2. Storage Cabinets: Secure storage for welding equipment and consumables is essential for maintaining order and protecting valuable tools.

- Lockable Cabinets: Providing security and protection, lockable cabinets are ideal for storing expensive equipment and materials.

- Mobile Storage Units: These units can be moved around the workshop, offering flexible storage solutions.

Conclusion

Optimizing your welding table with the right accessories can significantly enhance both efficiency and quality in your welding tasks. From clamping tools and positioning aids to safety equipment and storage solutions, each accessory plays a crucial role in improving workflow and precision. By investing in these essential tools, welders can create a more productive, safe, and organized workspace, ultimately leading to better welding outcomes. For more information on welding table accessories, visit GPPH’s product page.